CNC

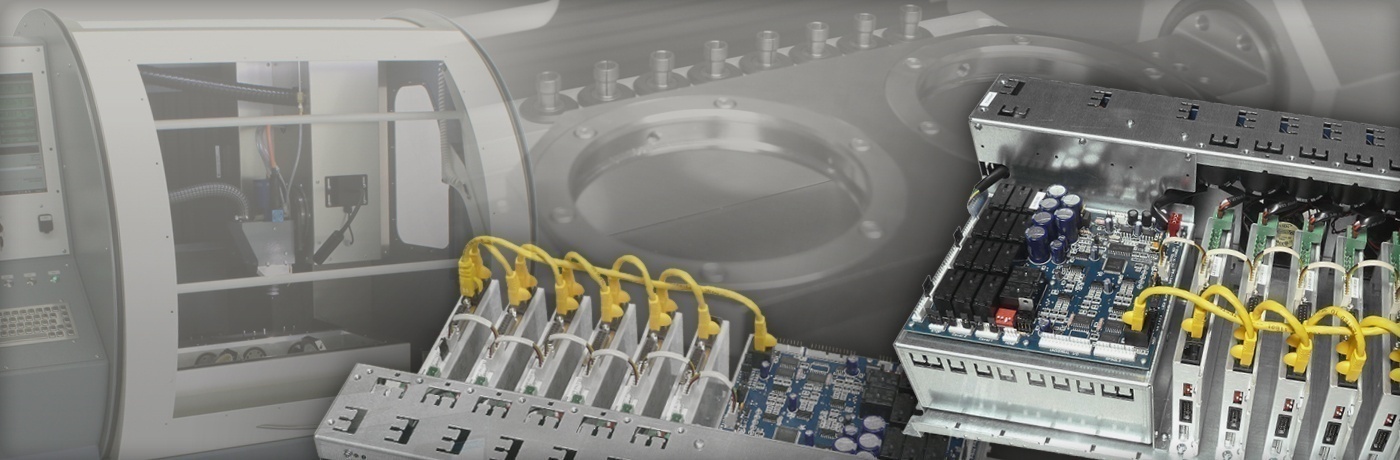

Multi-Axis CNC Servo Controller

Highly integrated, cost-effective multi-axis servo control package designed for CNC machine control applications. The unit employs modular single axis intelligent servo drives capable of performing precise coordinated motion control.

In native mode of operation all servo axes are controlled via high-speed serial bus connected to RS-485 or USB port on the host computer. Alternatively the drives can be utilized in ±10V analog or step/direction modes in conjunction with external motion controller. Optional dual-loop encoder interface is available to support two encoder inputs per axis for improved absolute accuracy.

The controller delivers up to 20A peak (12A continuous) current per motor channel, supporting sinusoidal control of linear and brushless/brushed rotary motors up to 1.5 horsepower.

Equipped with various 100% relay contact based safety interlock functions such as power supply control interface, spindle control interface with safety enable/stop mechanical relay output, dual line emergency stop button control, dual contact work zone covers with lock/unlock, dual line NC/NO safe zone sensors.

LS-2315 High Performance Spindle Drive

High performance spindle motor drive designed for control of HF spindle motors up to 1KW and 100,000 rpm. Drive’s controls allow applications under LS-2310 control or standalone mode. Dual analog input interface can be used for flexible implementation of fixed and variable speed control. Inverter frequency range: 83.3Hz to 1666.6Hz. Dry contact spindle stopped output.

LS-231SE Advanced Multifunctional Servo Drive

Multifunctional single-axis servo controller with integrated power amplifier designed for applications requiring sinusoidal control of linear and brushless/brushed rotary motors up to 1.5 horsepower. Multiple digital and analog modes of operation include high-speed RS-485, step/direction, step positive/negative, quadrature encoder slave, dual encoder. High-resolution encoders can be used for precise position control. LS-231SE is equipped with various safety features such as short circuit protection for the motor and the drive, limit switch inputs, over/under voltage shutdown and encoder presence control. Safety bus can be connected for multi-drive system protection. The maximum motor output current and overload time can be set.

LS-2310 Supervisor I/O Controller

Essential module specifically designed for CNC machines is an I/O controller with specialized interface for supervising of motor power supply, spindle, safe zone sensors, work zone covers, tool changer, eight short protected digital outputs and seven universal digital inputs. LS-2310 is designed as a member of Logosol Distributed Control Network (LDCN).

LS-2317 Manual Pulse Generator

Manual pulse generator with up to 6-axis selection, three scaling factor selection, MPG enable input, MPG encoder presence control, and dual line emergency stop.

CNC Software

Allows users to load and execute G-code files on CNC machines controlled by Logosol intelligent servo drives for coordinated motion control such as LS-231. The application supports also LS-2310 supervisor I/O controller, LS-2315 spindle controller and additional distributed I/O controllers. Easily customizable for specific machine configuration.

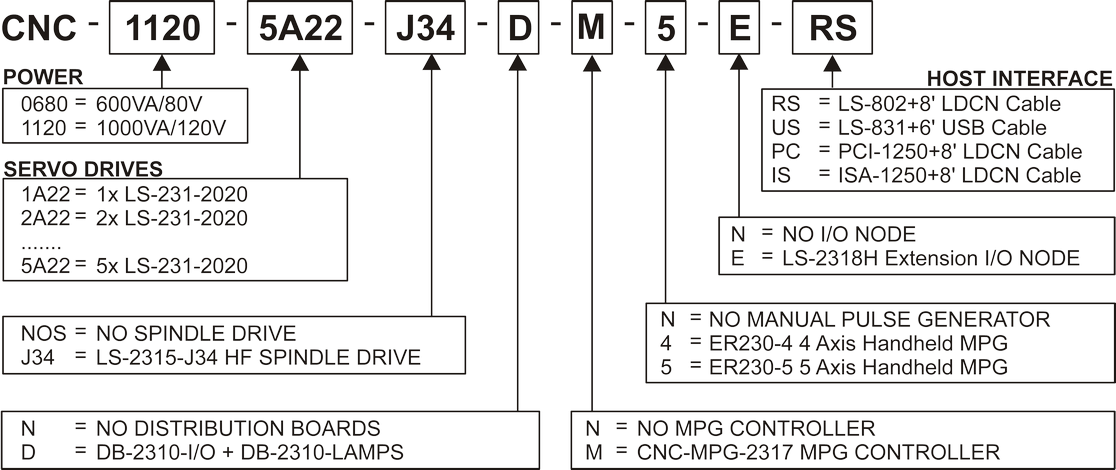

CNC System Ordering Guide